PET Light Diffusion Film

Product Introduction

| PET Light Diffusion Film | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Detailed description: | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

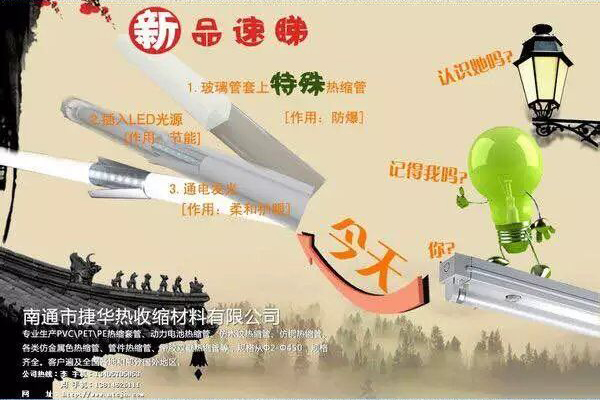

1. Explosion-proof LED light diffusion PET heat shrink film

This product is used in LED glass T5.T6.T8.T10.T12. Tube casing engineering, mainly diffusion point light source, insulation, protection of glass rupture does not cause harm.

Relative to the original PC shade with cheap, long time without bending, cooling effect, diffusion and light transmission performance is excellent.

The role of white light diffusion PET heat shrinkable tube is the LED fluorescent lamp point light source evenly converted into surface light source, to achieve the effect of uniform light. Light diffusion heat shrink tubing The principle of uniform light is the use of light in different refractive index of the media through the light to produce a lot of refraction, reflection, scattering, access to optical diffusion effect. Transmittance can reach 85-93%, haze 95-99%, according to customer requirements processing production. Green: in line with EU RoHS directive requirements, and no traditional energy-saving lamps of mercury and ultraviolet pollution, energy-saving low-carbon, Nantong Jiehua heat for your well-made.

2, Heat Shrink Casing Size & Shrink Standard:

Note: color size can be produced according to customer requirements.

3、Casing characteristics standards and test methods:

4、Instructions:

With the length of the glass lamp to increase the number of two additional 5MM to cut the light diffusion heat shrink tube, the cutting light will be a good heat shrinkable tube (wear clean gloves) set in the alcohol scrubbed over And drying the glass tube, and then into the constant temperature thermal cycle tunnel furnace 75-85 ℃, 1-2 minutes to shrink, to be contraction of the tube to see if it is not completely heat shrinkage, no words, you can then shrink, The temperature is too high, the product crystallization, there will be black spots, after cooling the knife repair edge, check the appearance of no exception can be assembled. Light diffusion heat shrinkable tube, light diffusion shrink film, fluorescent tube heat shrinkable tube, fluorescent heat shrinkable film, LED light diffusion PET heat shrinkable film, LED fluorescent light diffusion film |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Jiehua heat shrink for your professional build, look forward to your phone -13814626111 Mr. Zhou

Related Products

- Silicone Heat Shrinkable Tube

- Fiberglass Tube

- PET Light Diffusion Film

- Environmental Double Wall Heat Shrinkabl···

Sales Network

Tel: 86-513-68835677

Business Manager: Li Haidong (+86-13405705853)

Heat Shrinkable Tube Factory: Zhou Weizhong (+86-13814626111)

ADD:Yuan Qiao Industrial Zone, 867 Tong Jing Road, Nantong, Jiangsu